Product Description

Quick Details

| Applicable Industries:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Energy & Mining, Other |

Customized support:

OEM, ODM |

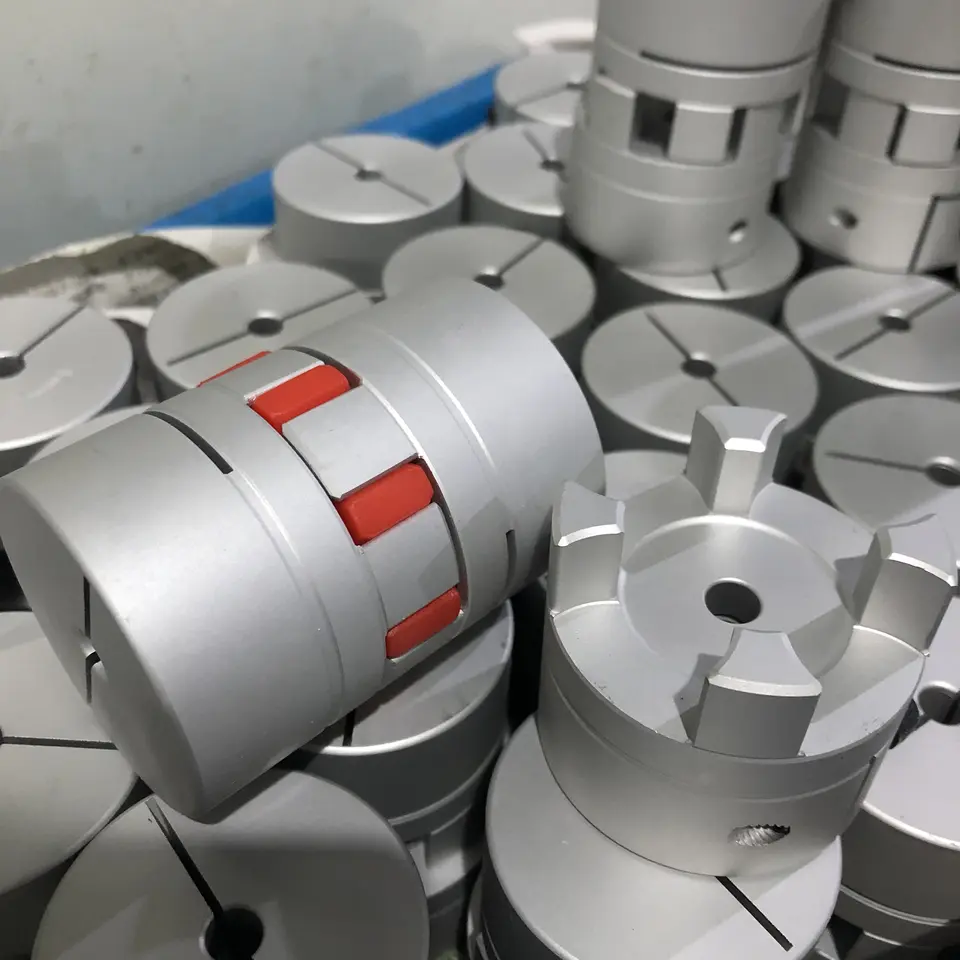

| Product name:RGE GR Jaw Coupling | Surface treatment: Anodizing |

| Place of Origin:ZheJiang , China | Brand Name:REACHJY |

| Application:transmission | Material: steel |

| Certification:ISO9001 | |

Features and Advantages of Jaw Couplings

Features:

1. Small and compact structure, low weight and large transmission torque altogether greatly improve mechanical movement in terms of quality and stability and absorb shock from uneven operation of power machine.

2. Protect machine functioning, dampen and reduce vibrations and shock appearing in movement and correct deviation and axial, radial and angular mounting.

3. Claw coupling 14 and beyond can be mounted horizontally or vertically with torsion angle reaches to 5° at maximum.

Advantades:

1. Realize massive production to support industrial leaders home and abroad after years of R&D.

2. Introduce German qualified TPU to produce metal parts and manufacture elastomer in large volume on our own.

3. Explosion prevention certified.

4. Satisfy transmission requirement when the torque exceeds 50% of the maximum level instantaneously.

5. Pass life test at high & low temperature and ensure service life even the load reaches to the maximum level.

6. Improved test bench applied.

Brief introduction of our company

Started in 1993, become REACH joint-venture factory in 2008, start export business in 2571, developed countries are the main market;National high-tech enterprise, “Specialized, fined, peculiar and innovative”enterprise of ZheJiang ; enterprise technology center of ZheJiang Province.

Located in ZheJiang , Southwest China, spHangZhou an area of 60,000 square meters,1km away from highway.

Approximately 380 employees, owns over 600 CNC machines, permanent property around $20 million.

7 production lines, including timing belt pulleys, gears, locking devices, couplings, surface treatment, and flange riveting.

Main products are critical and high-precision Power Transmission components, control system and equipments including locking devices(motor locking devices for new energy automobile),timing belt pulleys,gears(high-precision pulleys for robot), high precision couplings, torque limiter, wind power products and other OEM parts.

Dedicated to be a international, professional supplier of power transmission components for medium-to-high clients; quality comes first and always satisfy the customers.

Our main products

Application

1. Widely used in mining, textile, printing, office, food equipment and other power transmission field and hydraulic field.

2. The high-precision timing belt pulleys, couplings and new energy expansion sets produced by Reach Xihu (West Lake) Dis.an are mainly used in industrial robots, elevator industry, precision machine tools, medical instruments and new energy vehicle industry

Three Advantages

•Strong R & D capacity

National high-tech enterprise, enterprise technology center of ZheJiang Province.

30 years experiences in the industry, owns 33 national patents.

Customized service, provide complete technical solution according to customer requirements.

•No defects system

Assure no defect with improved quality control & inspection systems and sophisticated facilities.

Apply ERP system and learn production to achieve scientific and orderly development.

•Cost advantages

Manufacturing factory, price and advantages.

Intelligent manufacturing, low cost.

Our workshop

Global Market /2571

Certification

the technological process of production

Process and Machine Photo Show

Some certificates of honor

FAQ:

1.Q: Are you a factory or trade company?

A: We are factory wtih more than 350 staffs and over 600 machine equipments.

2.Q: When can I get the quotation?

A: We are usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, you can call me directly or send me an email to get the inquiry priority.

3.Q: Do you like to serve the client only with small order?

A: We enjoy to grow up together with our clients whatever big or small.

4.Q: Can you send me a free sample?

A: Yes. We can send you sample for checking our quality. But you need to pay for the sample first, and we will refund you once you place a mass order from us.

5.Q: Could you tell me the packing of your goods?

A: Put a big plastic bag into a wooden case–>(optional)Packaging each product in a anti-rust paper/white box/-Settle the location with a card board-> seal the plastic bag–> Cover the wooden case–>Wrap the wooden case with the steel beltnow–>Label–> Completed.

6. Q: What is your MOQ?

A: 1). In stock: MOQ is 1pcs.

2). Not in stock:

When the out diameter is less than 50mm, the MOQ is 100pcs;

When the out diameter is more than 50mm and less than 300mm, the MOQ is 50pcs;

When the out diameter is more than 300mm, the MOQ is 10pcs.

7. Q: What is your terms of payment?

A:1).100% Western Union or PayPal in advance ,specially for small amount.

2).100% T/T or western union in advance for small quantity order.

3).30% T/T in advance, pay the balance payment before delivery the goods.

4).100% payment on Alibaba.

8. Q: What are your terms of delivery?

A: EXW, FOB/CIF ZheJiang or ZheJiang .

9. Q: What is the shipment time?

A: 1).By air to air port: Fastest, usually 3 days or 4 days.

2).By sea to sea port: Cheapest, usually 15 days to 30 days.

3).By courier: DHL, FedEx, ..usually 5 days to 7 days.

10. Q: How to start an order with you?

A: You can send us an inquiry here, or send us an email, or call us directly!

You will get from our company:

1. Stable Quality.

2. Lower price-Not cheapest but the lowest at the same quality.

3. Good service-Satisfactory service before and after sale.

4. Professional design team and sales department for your service.

5. Direct manufacturers.

6. OEM & ODM available.

7. The punctual delivery of goods,quality and quantity guaranteed.

Our Services

1. Reply your inquiry within 24 hours.

2. Experienced staffs answer all your questions in fluent English.

3. We are the factory,so we will offer good quality of products with competitive price and the satisfactory services.

4. OEM,buyer design,buyer label services provided.

5. Exclusive and unique solution can be provide to our customer by our well-trained and professional engineers and staffs.

6. 7 days 24 hours online service.

Use of Jaw Couplings in Food Processing and Pharmaceutical Industries

Jaw couplings can be used in food processing and pharmaceutical industries under certain conditions and with the appropriate materials and design considerations. These industries have strict regulations and requirements regarding hygiene, contamination prevention, and cleanability. Here are some key factors to consider:

- Material Selection: For applications in food processing and pharmaceutical industries, jaw couplings must be made from materials that meet FDA and/or other regulatory standards for food contact and pharmaceutical use. Stainless steel or FDA-approved plastics are commonly used in such applications.

- Cleanability: The design of the jaw coupling should allow for easy cleaning and sanitization. Smooth surfaces and minimal crevices help prevent the accumulation of debris and bacteria. Hygienic designs are crucial to ensure compliance with industry standards.

- Sealing: Proper sealing is essential to prevent any lubricants or contaminants from escaping the coupling and coming into contact with the processed materials. Seal materials must be compatible with the substances used in the industry.

- Corrosion Resistance: In food processing and pharmaceutical environments, equipment is often subjected to aggressive cleaning agents and chemicals. Jaw couplings must be corrosion-resistant to withstand these harsh conditions and maintain their performance over time.

- Compliance with Regulations: Industries such as food processing and pharmaceuticals have specific regulatory standards, such as those set by the FDA (Food and Drug Administration) or other relevant authorities. The jaw couplings used in these applications must meet all necessary regulations to ensure product safety and consumer confidence.

It is important to note that while jaw couplings can be suitable for certain applications in food processing and pharmaceutical industries, it is essential to work closely with coupling manufacturers and suppliers to ensure that the selected couplings meet all industry-specific requirements and standards. Additionally, regular maintenance and inspection should be carried out to ensure the couplings continue to perform as expected and comply with hygiene and safety regulations.

How does a jaw coupling help in power transmission efficiency?

A jaw coupling plays a significant role in enhancing power transmission efficiency in mechanical systems. It achieves this by incorporating several design features that minimize energy losses and maximize the transfer of power from one shaft to another. Here are some ways in which a jaw coupling helps improve power transmission efficiency:

- Mechanical Flexibility: Jaw couplings utilize a flexible elastomer spider as the connecting element between the two shafts. This elastomer spider allows for a certain degree of angular and parallel misalignment between the shafts without imposing significant additional loads on the connected equipment. The mechanical flexibility of the elastomer helps reduce the generation of excess heat and vibration, thereby optimizing power transmission efficiency.

- Vibration Damping: The elastomer spider in a jaw coupling also acts as a vibration-damping element. It absorbs and dissipates vibrations generated during the operation of rotating machinery. By dampening vibrations, the coupling reduces energy losses due to mechanical oscillations, which can otherwise decrease the overall power transmission efficiency.

- Shock Absorption: In addition to damping vibrations, jaw couplings can handle sudden shocks and impacts that may occur during equipment operation. The elastomer spider’s ability to absorb shocks prevents sudden force spikes from propagating through the system and helps maintain steady power transmission, thus improving overall efficiency.

- Reduced Friction: The design of jaw couplings minimizes sliding friction between the shafts and the coupling components. This reduced frictional resistance results in lower energy losses and less heat generation during power transmission, contributing to higher efficiency in the system.

- Torsional Wind-Up Compensation: When torque is transmitted through the shafts, there can be some degree of torsional wind-up or twist in the coupling. Jaw couplings can compensate for this torsional movement, ensuring that the transmitted power reaches the intended equipment without significant losses due to torsional deformation.

- Simple and Robust Design: Jaw couplings have a simple construction, typically consisting of two hubs and an elastomer spider. This straightforward design reduces the number of moving parts and potential points of failure, resulting in a robust and reliable coupling. A reliable coupling minimizes the risk of power losses due to mechanical inefficiencies or breakdowns, thus improving overall power transmission efficiency.

In summary, a jaw coupling enhances power transmission efficiency by providing mechanical flexibility, vibration damping, shock absorption, reduced friction, and torsional wind-up compensation. Its simple and robust design further contributes to reliable power transmission. When selecting a jaw coupling for a specific application, it is essential to consider factors such as torque requirements, operating conditions, and misalignment compensation to ensure optimal efficiency and performance in the system.

Advantages of Using Jaw Couplings in Mechanical Systems

Jaw couplings offer several advantages in mechanical systems:

- Misalignment Compensation: Jaw couplings can tolerate angular, parallel, and axial misalignments between connected shafts, reducing the need for precise alignment during installation.

- Vibration Damping: The elastomeric spider in the jaw coupling absorbs shocks and vibrations, providing smoother operation and extending the life of connected equipment.

- Backlash-Free: Due to the tight fit between the jaws and the spider, jaw couplings are virtually backlash-free, enabling more accurate and responsive motion transfer.

- High Torque Capacity: Jaw couplings can handle high torque loads, making them suitable for a wide range of industrial applications.

- Easy Installation: With a simple design and few components, jaw couplings are easy to install and maintain.

- Cost-Effective: Compared to other types of couplings, jaw couplings are relatively cost-effective, providing reliable power transmission at a lower cost.

- Fail-Safe Design: In the event of a spider failure, the jaws can still maintain some torque transmission, allowing for limited operation and preventing sudden breakdowns.

Due to these advantages, jaw couplings are widely used in pumps, motors, fans, and various industrial machinery where misalignment, vibration, and torque transmission are critical factors.

editor by CX 2023-11-06