Product Description

Product Description

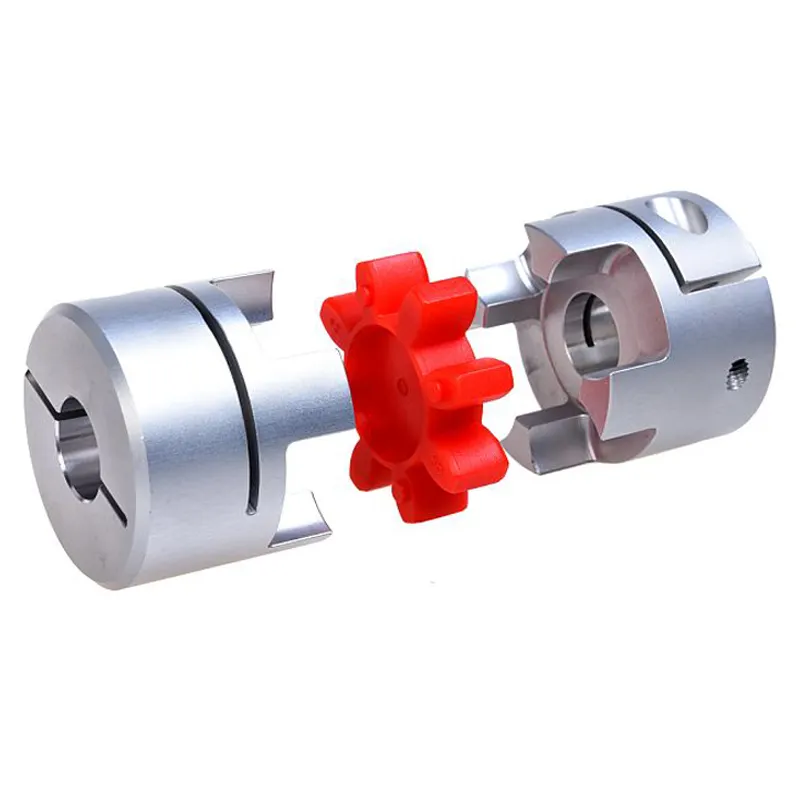

The Curved Jaw couplings can be utilized in many applications and serve as an all-purpose coupling. The basic design of the Curved Jaw allows for a higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it the high torque capacity, and reduces edge pressure. It will accommodate axial, radial and angular shaft misalignments. The hubs are produced from a variety of materials including; aluminum, gray iron, steel, sintered steel, and stainless steel. The spider elements are available in various durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles which include shock loading and can minimize torsional vibrations in the system.

Features of Curved Jaw Coupling/Rotex Coupling:

1.High efficiency zero backlash Curved Jaw Coupling/Rotex Coupling.

2.Rigid and flexible at the same time, different kinds of spiders of different hardness.

3.Light weight and compact design.

4.Can bear high speed and torque power transmission.

Techncial Date

Related Products

Manufacturing

Application

| KASIN No. | Hub Type | Max Speed RPM | Rated Torque/Nm | Pilot Bore | Finished Bore | L | L1; L2 | E | b | s | D1 | dH | D; D2 | N | G | t | |

| 98 Sh-A/Red | 92 Sh-A/Yellow | d | Min~Max | ||||||||||||||

| 19 | 1 | 167/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Using Jaw Couplings in Hydraulic and Pneumatic SystemsYes, jaw couplings can be used in both hydraulic and pneumatic systems to connect the driving and driven components. Jaw couplings are versatile and well-suited for various power transmission applications, including those involving fluid-based systems. Here’s how jaw couplings are compatible with hydraulic and pneumatic systems:

Overall, jaw couplings offer reliable power transmission in hydraulic and pneumatic systems, providing benefits such as flexibility, shock absorption, corrosion resistance, low inertia, and backlash prevention. However, it’s essential to consider factors such as operating conditions, temperature, and the type of fluid used when selecting a jaw coupling for a specific hydraulic or pneumatic application. What are the temperature and environmental limitations of jaw couplings?Jaw couplings, like many mechanical components, have temperature and environmental limitations that need to be considered for proper operation and longevity. These limitations are determined by the materials used in the construction of the jaw coupling and the specific operating conditions it will encounter. Here are some of the common temperature and environmental limitations of jaw couplings:

It is crucial to consult the manufacturer’s specifications and guidelines to ensure that the selected jaw coupling is suitable for the specific temperature and environmental conditions of the intended application. Proper maintenance, periodic inspections, and adhering to recommended operating parameters can extend the life and performance of the jaw coupling in a given environment. What is a Jaw Coupling and How Does It Work?A jaw coupling is a type of mechanical coupling used to connect two shafts in machinery. It is designed to transmit torque while compensating for shaft misalignments and dampening vibrations. The coupling consists of two hubs with three curved jaws each and an elastomeric spider placed between them. The working principle of a jaw coupling is based on the flexibility of the elastomeric spider. When the two hubs are brought together, the spider gets compressed between them. The curved shape of the jaws allows the spider to flex, accommodating angular and axial misalignments between the shafts. During operation, when torque is applied to one shaft, it is transmitted through the spider to the other shaft, enabling power transmission. The elastomeric material of the spider also acts as a damping element, reducing vibrations and shock loads in the system. Jaw couplings are commonly used in various applications, such as pumps, compressors, conveyors, and other power transmission systems. Their simple design, ease of installation, and ability to handle misalignments make them popular choices for connecting rotating shafts in machinery.

| |||||||||||||||