Product Description

Quick Details

| Applicable Industries:

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Energy & Mining, Other |

Customized support:

OEM, ODM |

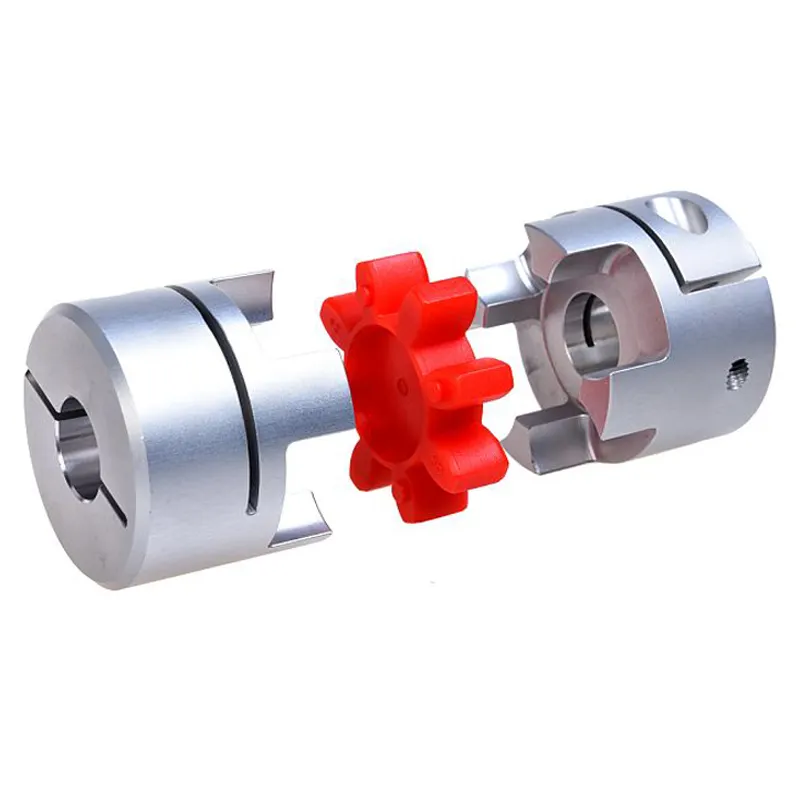

| Product name:RGE GR Jaw Coupling | Surface treatment: Anodizing |

| Place of Origin:ZheJiang , China | Brand Name:REACHJY |

| Application:transmission | Material: steel |

| Certification:ISO9001 | |

Features and Advantages of Jaw Couplings

Features:

1. Small and compact structure, low weight and large transmission torque altogether greatly improve mechanical movement in terms of quality and stability and absorb shock from uneven operation of power machine.

2. Protect machine functioning, dampen and reduce vibrations and shock appearing in movement and correct deviation and axial, radial and angular mounting.

3. Claw coupling 14 and beyond can be mounted horizontally or vertically with torsion angle reaches to 5° at maximum.

Advantades:

1. Realize massive production to support industrial leaders home and abroad after years of R&D.

2. Introduce German qualified TPU to produce metal parts and manufacture elastomer in large volume on our own.

3. Explosion prevention certified.

4. Satisfy transmission requirement when the torque exceeds 50% of the maximum level instantaneously.

5. Pass life test at high & low temperature and ensure service life even the load reaches to the maximum level.

6. Improved test bench applied.

Brief introduction of our company

Started in 1993, become REACH joint-venture factory in 2008, start export business in 2571, developed countries are the main market;National high-tech enterprise, “Specialized, fined, peculiar and innovative”enterprise of ZheJiang ; enterprise technology center of ZheJiang Province.

Located in ZheJiang , Southwest China, spHangZhou an area of 60,000 square meters,1km away from highway.

Approximately 380 employees, owns over 600 CNC machines, permanent property around $20 million.

7 production lines, including timing belt pulleys, gears, locking devices, couplings, surface treatment, and flange riveting.

Main products are critical and high-precision Power Transmission components, control system and equipments including locking devices(motor locking devices for new energy automobile),timing belt pulleys,gears(high-precision pulleys for robot), high precision couplings, torque limiter, wind power products and other OEM parts.

Dedicated to be a international, professional supplier of power transmission components for medium-to-high clients; quality comes first and always satisfy the customers.

Our main products

Application

1. Widely used in mining, textile, printing, office, food equipment and other power transmission field and hydraulic field.

2. The high-precision timing belt pulleys, couplings and new energy expansion sets produced by Reach Xihu (West Lake) Dis.an are mainly used in industrial robots, elevator industry, precision machine tools, medical instruments and new energy vehicle industry

Three Advantages

•Strong R & D capacity

National high-tech enterprise, enterprise technology center of ZheJiang Province.

30 years experiences in the industry, owns 33 national patents.

Customized service, provide complete technical solution according to customer requirements.

•No defects system

Assure no defect with improved quality control & inspection systems and sophisticated facilities.

Apply ERP system and learn production to achieve scientific and orderly development.

•Cost advantages

Manufacturing factory, price and advantages.

Intelligent manufacturing, low cost.

Our workshop

Global Market /2571

Certification

the technological process of production

Process and Machine Photo Show

Some certificates of honor

FAQ:

1.Q: Are you a factory or trade company?

A: We are factory wtih more than 350 staffs and over 600 machine equipments.

2.Q: When can I get the quotation?

A: We are usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, you can call me directly or send me an email to get the inquiry priority.

3.Q: Do you like to serve the client only with small order?

A: We enjoy to grow up together with our clients whatever big or small.

4.Q: Can you send me a free sample?

A: Yes. We can send you sample for checking our quality. But you need to pay for the sample first, and we will refund you once you place a mass order from us.

5.Q: Could you tell me the packing of your goods?

A: Put a big plastic bag into a wooden case–>(optional)Packaging each product in a anti-rust paper/white box/-Settle the location with a card board-> seal the plastic bag–> Cover the wooden case–>Wrap the wooden case with the steel beltnow–>Label–> Completed.

6. Q: What is your MOQ?

A: 1). In stock: MOQ is 1pcs.

2). Not in stock:

When the out diameter is less than 50mm, the MOQ is 100pcs;

When the out diameter is more than 50mm and less than 300mm, the MOQ is 50pcs;

When the out diameter is more than 300mm, the MOQ is 10pcs.

7. Q: What is your terms of payment?

A:1).100% Western Union or PayPal in advance ,specially for small amount.

2).100% T/T or western union in advance for small quantity order.

3).30% T/T in advance, pay the balance payment before delivery the goods.

4).100% payment on Alibaba.

8. Q: What are your terms of delivery?

A: EXW, FOB/CIF ZheJiang or ZheJiang .

9. Q: What is the shipment time?

A: 1).By air to air port: Fastest, usually 3 days or 4 days.

2).By sea to sea port: Cheapest, usually 15 days to 30 days.

3).By courier: DHL, FedEx, ..usually 5 days to 7 days.

10. Q: How to start an order with you?

A: You can send us an inquiry here, or send us an email, or call us directly!

You will get from our company:

1. Stable Quality.

2. Lower price-Not cheapest but the lowest at the same quality.

3. Good service-Satisfactory service before and after sale.

4. Professional design team and sales department for your service.

5. Direct manufacturers.

6. OEM & ODM available.

7. The punctual delivery of goods,quality and quantity guaranteed.

Our Services

1. Reply your inquiry within 24 hours.

2. Experienced staffs answer all your questions in fluent English.

3. We are the factory,so we will offer good quality of products with competitive price and the satisfactory services.

4. OEM,buyer design,buyer label services provided.

5. Exclusive and unique solution can be provide to our customer by our well-trained and professional engineers and staffs.

6. 7 days 24 hours online service.

Using Jaw Couplings in Hydraulic and Pneumatic Systems

Yes, jaw couplings can be used in both hydraulic and pneumatic systems to connect the driving and driven components. Jaw couplings are versatile and well-suited for various power transmission applications, including those involving fluid-based systems. Here’s how jaw couplings are compatible with hydraulic and pneumatic systems:

- Flexibility: Jaw couplings are made of flexible materials, such as elastomers, which allow for some angular, parallel, and axial misalignment between the shafts. In hydraulic and pneumatic systems, where vibrations and movements are common, the jaw coupling’s ability to accommodate misalignment helps reduce stress on the connected components.

- Shock Absorption: Hydraulic systems often experience pressure surges and hydraulic shocks due to rapid changes in fluid flow. Similarly, pneumatic systems may encounter air pressure fluctuations. Jaw couplings can absorb shocks and vibrations, protecting the system from sudden jolts and minimizing wear on components.

- Corrosion Resistance: Some jaw couplings are available in materials that offer excellent corrosion resistance, making them suitable for hydraulic systems working with hydraulic fluids and pneumatic systems handling compressed air, which may contain moisture.

- Low Inertia: Jaw couplings have low inertia, which is advantageous in applications where quick start-stop responses are required. This characteristic is beneficial in hydraulic and pneumatic systems that need rapid and precise movements.

- Backlash Prevention: Backlash, which can lead to vibrations and inaccuracies, is minimized with jaw couplings. This feature is beneficial in hydraulic and pneumatic systems where precise positioning is crucial.

- Simple Installation: Jaw couplings are easy to install and require minimal maintenance, making them suitable for various hydraulic and pneumatic applications.

- Compatibility with Shaft Sizes: Jaw couplings are available in different sizes and configurations, allowing for compatibility with various shaft diameters commonly found in hydraulic and pneumatic systems.

Overall, jaw couplings offer reliable power transmission in hydraulic and pneumatic systems, providing benefits such as flexibility, shock absorption, corrosion resistance, low inertia, and backlash prevention. However, it’s essential to consider factors such as operating conditions, temperature, and the type of fluid used when selecting a jaw coupling for a specific hydraulic or pneumatic application.

Can jaw couplings be used in heavy-duty applications such as mining and construction?

Yes, jaw couplings can be used in heavy-duty applications such as mining and construction, but their suitability depends on various factors. Jaw couplings are commonly employed in a wide range of industrial applications due to their versatility and ability to handle misalignment. However, when considering their usage in heavy-duty environments, several important aspects need to be taken into account:

- Torque and Power Requirements: Heavy-duty applications often involve high torque and power demands. It is crucial to ensure that the selected jaw coupling is rated to handle the specific torque and power levels encountered in the mining and construction machinery. Choosing a coupling with a sufficient torque capacity ensures reliable power transmission without premature failure.

- Material Strength: The materials used in the construction of jaw couplings play a critical role in their ability to withstand heavy-duty applications. Couplings made from robust materials, such as high-strength steel or alloy materials, are better suited for withstanding the demanding conditions found in mining and construction equipment.

- Impact and Shock Resistance: Mining and construction applications involve significant levels of impact and shock loads due to the nature of the work. The jaw coupling must be designed to handle these dynamic loads without compromising its structural integrity. Some jaw couplings feature specially designed elastomers or flexible elements that provide additional shock absorption and reduce the transmitted impact forces.

- Dust and Debris Management: Heavy-duty environments like mining and construction sites often contain high levels of dust, dirt, and debris. These particles can accumulate on the coupling surfaces and lead to premature wear and reduced performance. Selecting jaw couplings with appropriate sealing mechanisms or protective covers can help minimize the ingress of contaminants and extend the coupling’s life in such environments.

- Maintenance and Inspection: Regular maintenance and inspection are crucial in heavy-duty applications to identify any signs of wear, misalignment, or damage to the coupling. Proper maintenance practices can prevent unexpected failures and ensure the equipment operates efficiently and safely.

When considering the use of jaw couplings in heavy-duty applications like mining and construction, it is essential to consult with coupling manufacturers or engineering experts to select the appropriate coupling type and size for the specific application. Some heavy-duty applications might require more specialized coupling designs, such as grid couplings, gear couplings, or disc couplings, which are explicitly engineered for extreme conditions and higher torque capacities. Additionally, following the manufacturer’s guidelines and recommendations for coupling installation, maintenance, and operating parameters is critical to ensure reliable and safe operation in heavy-duty environments.

Handling Angular, Parallel, and Axial Misalignment with Jaw Couplings

Jaw couplings are designed to handle various types of misalignment that can occur between the shafts they connect. These misalignments include:

- Angular Misalignment: When the shafts are not aligned in a straight line and have an angular offset, jaw couplings can accommodate this misalignment due to the flexibility of their elastomeric spider. The spider allows for a limited amount of angular movement between the hubs, reducing stress on the connected equipment.

- Parallel Misalignment: Parallel misalignment occurs when the shafts are not perfectly aligned but are parallel to each other. Jaw couplings can handle parallel misalignment to some extent, thanks to the elastomeric spider’s ability to flex and offset slight shaft misalignments.

- Axial Misalignment: Axial misalignment refers to the displacement of shafts along their rotational axis. While jaw couplings are primarily designed for torque transmission and misalignment compensation, they have limited capability to handle axial misalignment. Excessive axial misalignment can lead to premature wear and reduce the coupling’s effectiveness.

It’s important to note that jaw couplings have specific misalignment limits, and exceeding these limits can lead to increased wear and decreased performance. Regular maintenance and inspection of jaw couplings are essential to ensure they are operating within acceptable misalignment parameters.

editor by CX 2023-11-30