Product Description

We work on this product for more than 10 years and could supply 1 stop solution on the hose coupling and pipe fittings. We mainly supply these couplings to our customer. Such as Camlock coupling, Air hose coupling, Bauer coupling, fire fighting couplings ( Stroz coupling, Guillenmin couplings, John Morris couplings, Machino coupling, Barcelona coupling, Forest couplings, fire nozzles), pipe fittings(stainless steel pipe fittings, malleable iron pipe fittings, flanges, sanitary pipe fittings) and valves ( ball valve, gate valve, sanitary butterfly valve ) and so on.

Adavantage of Air hose coupling:

Good abrasion resistant, light weight, economical cost;

Save time compared with flanged or threaded fittings;

No tools needed and make the job easy;

Safety sealing for fluids, powders and pellets,Light weight and durable;

Could keep the transfers safe without any damage or any risks.

Detailed description:

| product | European type universal air hose coupling |

| Key words | Air hose fitting, claw coupling, claw fitting, air hose adapter, air hose coupler, |

| Material | Carbon steel zn plated, Stainless steel, malleable iron |

| Size | 1/4″-2″ for 2 lug |

| seal | NBR |

| Thread | BSP |

| part | male end, female end, hose end with collar, hose end without collar |

| Method | Investment casting/Sand casting |

| Pressure | Working pressure: 10bar Max test pressure: 16bar |

| Application | use for air hose and sandblast hose |

| Place of origin | ZheJiang , China |

| Package | Plastic bag and Cartons then Pallet |

| advantage | quick, safey and no need tools |

| Delivery | By sea, By air and By express |

| Lead time | withinn 35-45 days after confiming the normal order |

Company Information:

Our types:

Certification:

Application:

When you choose the camlock couplings, please confirm the details such as:

1, Types and Size

2, Material

3, Thread

4, Seals

5, Presuure and Tempreture

6, Standard: A-A-59326 or DIN2828.

OUR SERVIC

Pre-sale service

1.We have stock and could deliver goods within short time.

2.OEM order are accepted, logo printing are available.

3.Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you.

4.All of our products are produced by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service.

After you choose:

1. We will check cheapest shipping cost and make invoice to you at once.

2. Check quality and package again, then send out to seaport at 1-2 weekdays after your payment

3. Email you the tracking no., and help to CHINAMFG the parcels until you signed them and update you the situation.

After-sale service

1.We are very glad that customers give us some suggestion for price and products.

2.If you have any question,please contact us freely by E-mail or Telephone or Whatsapp or Skpye.

FAQ

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge and need your side pay the cost of freight.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 25-35 days if the goods are not in stock, it is according to quantity.

Q. what is your payment term?

A: T/T 30% payment in advance, balance to be paid before shipment. or L/C. Or West Union, Paypal and Money Gram if little value.

Q: what is your main market?

A: North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe.

Q: Can I have my own customized product?

A: Yes, we can supply logo Print and package desiged based in our MOQ.

Contact us

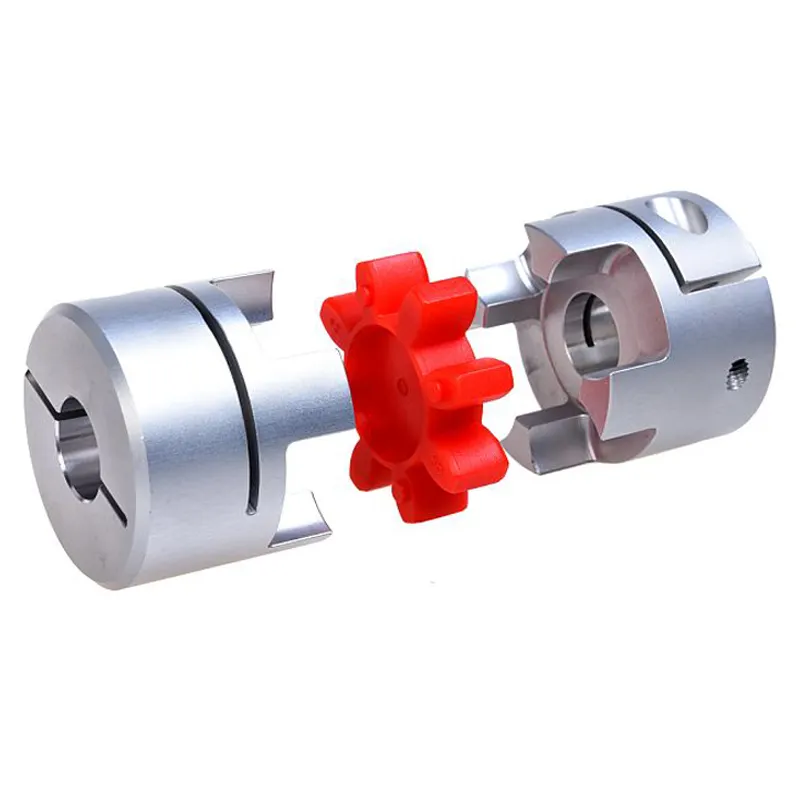

Impact of Jaw Coupling on the Overall Reliability of Connected Equipment

A jaw coupling plays a critical role in enhancing the overall reliability of connected equipment in mechanical power transmission systems. Its design and features contribute to various aspects that positively influence reliability:

- Misalignment Compensation: One of the key benefits of jaw couplings is their ability to accommodate misalignment between shafts. By allowing for angular, parallel, and axial misalignment, the jaw coupling reduces stress on connected equipment. It helps prevent excessive forces and shaft bending that can lead to premature wear or failure.

- Shock Absorption: The elastomeric spider element used in jaw couplings acts as a shock absorber. It dampens vibrations and shock loads, protecting connected equipment from sudden jolts or impacts that could cause damage or fatigue over time.

- Torsional Damping: Jaw couplings provide torsional damping, reducing the risk of torsional vibrations that can negatively affect equipment performance. By minimizing vibrations, the coupling contributes to smoother operation and extended equipment life.

- Fail-Safe Design: In the event of a spider failure, jaw couplings often offer a fail-safe design. The spider is a replaceable component, and its failure does not typically lead to catastrophic failure of the coupling or connected equipment. This characteristic enhances the overall system reliability and simplifies maintenance.

- Low Maintenance: Jaw couplings are relatively low maintenance compared to other coupling types. The elastomeric spider does not require lubrication and has a longer service life compared to metallic couplings. This reduces the frequency of maintenance activities, minimizing downtime and increasing equipment reliability.

- Backlash-Free Operation: Some jaw couplings are designed to provide backlash-free operation, ensuring accurate motion transmission without play or clearance. This feature is particularly important in precision systems, preventing positioning errors and contributing to consistent performance.

- Corrosion Resistance: Jaw couplings are available in various materials, including stainless steel and corrosion-resistant alloys. Choosing the appropriate material for the specific environment ensures the coupling’s longevity and reliability, even in harsh operating conditions.

- Reduced Vibration Transfer: By isolating vibrations, jaw couplings prevent the transfer of harmful vibrations between connected equipment. This safeguard is crucial in delicate systems where excessive vibrations could lead to malfunction or damage.

Overall, a well-chosen and properly installed jaw coupling positively impacts the reliability of connected equipment. It helps prevent mechanical stress, dampens vibrations, and provides a reliable connection between shafts, contributing to the smooth and efficient operation of the entire mechanical system.

How does a jaw coupling help in torque and rotational speed control?

A jaw coupling plays a vital role in torque and rotational speed control by facilitating efficient power transmission while compensating for misalignments and dampening vibrations. Here’s how a jaw coupling helps in achieving torque and rotational speed control:

- Torque Transmission: Jaw couplings are designed to transmit torque between two shafts with minimal power loss. The elastomer spider, which acts as the flexible element between the two coupling hubs, efficiently transfers torque from one shaft to the other. This precise torque transmission is essential in maintaining consistent rotational motion and controlling the speed of the driven equipment.

- Misalignment Compensation: In rotating machinery, misalignments between the motor and driven equipment are common due to factors like installation errors, thermal expansion, or shaft deflection. Jaw couplings can handle both angular and parallel misalignments. By accommodating these misalignments, jaw couplings ensure smooth operation and prevent unnecessary stress on the equipment, thus contributing to torque and rotational speed control.

- Vibration Damping: Vibrations are an inherent characteristic of rotating machinery and can affect torque and rotational speed stability. The elastomer spider in the jaw coupling acts as a damping element, absorbing and dissipating vibrations. This vibration damping capability reduces the risk of speed fluctuations and enhances overall system stability during operation.

- Start-Up and Overload Protection: During start-up or when the driven equipment experiences sudden overload conditions, there may be spikes in torque and rotational speed. Jaw couplings, with their torsional flexibility, can absorb these sudden torque variations, protecting the equipment from damage and providing smoother start-up and operation.

The combination of precise torque transmission, misalignment compensation, vibration damping, and overload protection makes jaw couplings effective in achieving torque and rotational speed control. However, it is essential to choose the appropriate jaw coupling size and material for the specific application to ensure optimal performance and reliability.

For applications that require even higher torque capacity or stricter speed control, specialized coupling types like gear couplings or servo couplings may be more suitable. These couplings offer advanced features for precision motion control and torque transmission in more demanding applications.

Materials Used in Manufacturing Jaw Couplings

Jaw couplings are commonly made from various materials, each offering different properties and suitability for specific applications. Some of the commonly used materials include:

- Polyurethane (PU): PU jaw couplings are known for their flexibility, high elasticity, and resistance to abrasion. They are ideal for applications requiring vibration dampening and shock absorption.

- Aluminum: Aluminum jaw couplings are lightweight, corrosion-resistant, and have good thermal conductivity. They are commonly used in low-to-medium torque applications.

- Steel: Steel jaw couplings offer high strength and durability, making them suitable for heavy-duty applications with high torque requirements.

- Stainless Steel: Stainless steel jaw couplings are resistant to corrosion and are often used in applications where there is exposure to moisture, chemicals, or harsh environments.

- Bronze: Bronze jaw couplings are known for their excellent wear resistance and low coefficient of friction, making them suitable for applications with high-speed and low lubrication.

- Acetal: Acetal jaw couplings provide good chemical resistance and low moisture absorption, making them suitable for applications where chemical exposure is a concern.

- Nylon: Nylon jaw couplings offer good strength, flexibility, and resistance to wear and chemicals, making them suitable for various industrial applications.

The choice of material depends on factors such as torque requirements, environmental conditions, operating speeds, and budget considerations. Engineers and designers select the appropriate material to ensure that the jaw coupling can perform optimally and withstand the demands of the application.

editor by CX 2023-12-04