Product Description

Female Threads With Lock Guillemin With Helical Shank Jaw Coupling

The standard of Guillemin Coupling is EN14420-8 or NF E29572. Materials are mainly stainless steel, aluminum, polypropylene and brass. Guillemin hose couplings is connected with thread and locking ring (latch). It can be used with DIN2817 safety clamp. Working pressure is 10 bar. Guillemin coupling is widely used in industries of oil, chemical, fire protection, paper manufacture, construction and metallurgy.

Guillemin couplings, also referred to as French couplings are symmetrical couplings where to identical halves are assembled by joining the lugs and turning the locking ring to ensure a good connection.

Pros:

Simple and easy connection

Has a locking ring and soft seal

Large free flow area

Aluminum couplings are lighter in weight than stainless steel

Suitable for water, fluids, hydrocarbons, chemicals, and dry loose materials

| Product Name: | Guillemin Camlock Coupling |

| Sizes: | 1” – 4” (DN25-DN100) |

| MOQ: | 50 pcs |

| Certificates: | CE, ISO9001:2015 |

| Standard: | EN14420-8 /NF E29572 |

| Material: | Stainless steel 316/ 304, Aluminum, PP |

| Working pressure: | 10 bar |

| Feature: | Light, flexible and interchangeable. To connect and disconnect without a tool. Economical |

| Application: | it is widely used in oil, chemical industry, fire fighting, paper manufacture, constructoin and metallurgy |

| HS code: | 7609000000 |

Our Advantage

We are experienced as we have been in this industry as a manufacturer for more than 10 years. Both of quality and service are highly guaranteed. Absolutely prompt delivery. We can produce according to specific drawings from customers. Welcome OEM/ODM project. Strict control on quality. High efficient and well trained sale service team. ISO9001, CE and SGS certified.

FAQ

1.Q: Are you a producer or trading company?

A: We are an experienced manufacturer. We own production line and kinds of machines.

2.Q: Can you make our specific logo on the part?

A: Yes please provide me your logo and we will make your logo on the part.

3.Q: Can you manufacture products according to my drawings?

A: Yes we can manufacturer according to client’s drawings if drawings or samples are available. We are experienced enough to make new tools.

4. Q: Can I get some samples?

A: We are honored to offer you our samples. Normally it is for free like 3-5 pcs. It is charged if the samples are more than 5 pcs. Clients bear the freight cost.

5. Q: How many days do you need to finish an order?

A: Normally it takes about 30 days to finish the order. It takes more time around CHINAMFG season, or if the order involves many kinds of different products.

6. Q: What kind of rubber washer do you apply to camlock couplings?

A: Normally we use NBR gasket.

contact-info.html /* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

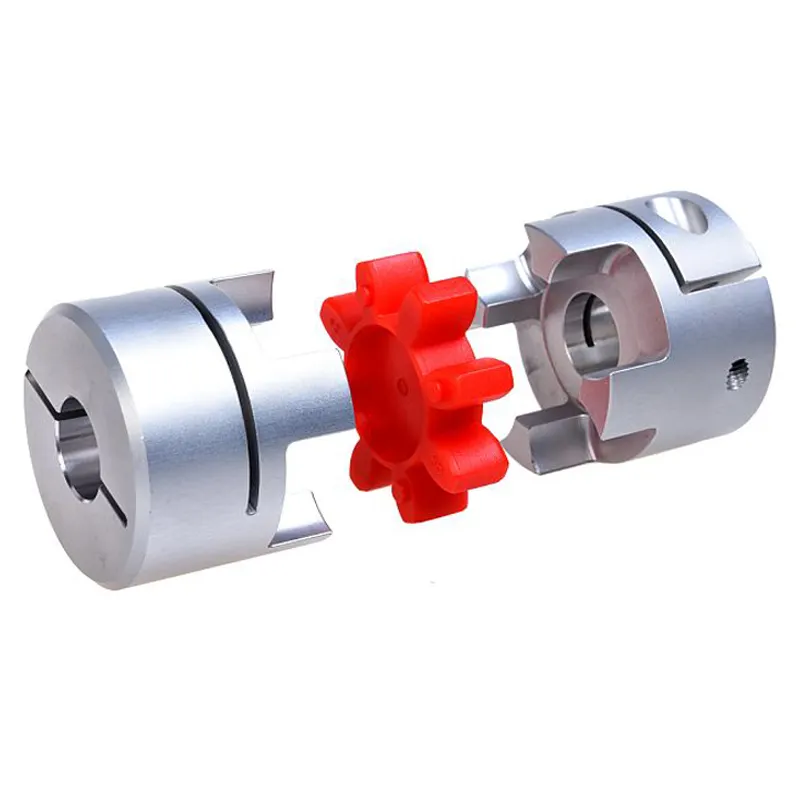

How do jaw couplings handle shaft misalignment in rotating equipment?

Jaw couplings are mechanical devices used in rotating equipment to connect two shafts and transmit torque. One of the key advantages of jaw couplings is their ability to handle shaft misalignment. Shaft misalignment can occur due to various reasons, including manufacturing tolerances, thermal expansion, foundation settling, or general wear and tear. Jaw couplings can accommodate misalignment in three primary ways:

- Angular Misalignment: Jaw couplings can handle small angular misalignments between the connected shafts. The flexible nature of the elastomer spider (the central element in the jaw coupling) allows for a certain degree of angular movement between the hubs without exerting excessive forces on the connected equipment.

- Parallel Misalignment: Parallel misalignment occurs when the two shafts are not perfectly aligned in a straight line. Jaw couplings can tolerate some amount of parallel misalignment due to the flexibility of the elastomer spider. This flexibility allows the hubs to move slightly relative to each other, thereby reducing the transmission of misalignment-induced forces to the equipment.

- Axial Misalignment: Axial misalignment refers to the offset between the axial positions of the connected shafts. While jaw couplings are primarily designed for torque transmission and misalignment compensation in angular and parallel directions, they can also handle minor amounts of axial misalignment due to the elastomer spider’s ability to absorb limited axial movement.

It is essential to note that jaw couplings have their limits in handling misalignment. Excessive misalignment beyond their design capabilities can lead to premature wear, reduced coupling life, and potential damage to the connected equipment. Therefore, it is crucial to understand the specific misalignment limits of the jaw coupling being used and ensure that the equipment operates within those limits.

In summary, jaw couplings handle shaft misalignment in rotating equipment by utilizing the flexibility of the elastomer spider to accommodate small angular, parallel, and axial misalignments. This feature helps protect the connected equipment from the detrimental effects of misalignment and ensures smooth and reliable operation.

How does a jaw coupling help in torque and rotational speed control?

A jaw coupling plays a vital role in torque and rotational speed control by facilitating efficient power transmission while compensating for misalignments and dampening vibrations. Here’s how a jaw coupling helps in achieving torque and rotational speed control:

- Torque Transmission: Jaw couplings are designed to transmit torque between two shafts with minimal power loss. The elastomer spider, which acts as the flexible element between the two coupling hubs, efficiently transfers torque from one shaft to the other. This precise torque transmission is essential in maintaining consistent rotational motion and controlling the speed of the driven equipment.

- Misalignment Compensation: In rotating machinery, misalignments between the motor and driven equipment are common due to factors like installation errors, thermal expansion, or shaft deflection. Jaw couplings can handle both angular and parallel misalignments. By accommodating these misalignments, jaw couplings ensure smooth operation and prevent unnecessary stress on the equipment, thus contributing to torque and rotational speed control.

- Vibration Damping: Vibrations are an inherent characteristic of rotating machinery and can affect torque and rotational speed stability. The elastomer spider in the jaw coupling acts as a damping element, absorbing and dissipating vibrations. This vibration damping capability reduces the risk of speed fluctuations and enhances overall system stability during operation.

- Start-Up and Overload Protection: During start-up or when the driven equipment experiences sudden overload conditions, there may be spikes in torque and rotational speed. Jaw couplings, with their torsional flexibility, can absorb these sudden torque variations, protecting the equipment from damage and providing smoother start-up and operation.

The combination of precise torque transmission, misalignment compensation, vibration damping, and overload protection makes jaw couplings effective in achieving torque and rotational speed control. However, it is essential to choose the appropriate jaw coupling size and material for the specific application to ensure optimal performance and reliability.

For applications that require even higher torque capacity or stricter speed control, specialized coupling types like gear couplings or servo couplings may be more suitable. These couplings offer advanced features for precision motion control and torque transmission in more demanding applications.

Selecting the Appropriate Jaw Coupling Size

Choosing the right jaw coupling size for a specific application involves considering several factors:

- Torque Requirements: Determine the maximum torque that the coupling will need to transmit in the application. Make sure to account for any peak or intermittent loads.

- Shaft Diameter: Measure the diameter of the shafts to be connected. The coupling’s bore size should match the shaft diameter for proper fit and secure power transmission.

- Speed: Consider the rotational speed of the application. High-speed applications may require special high-speed jaw couplings.

- Misalignment Compensation: Evaluate the level of misalignment present in the system, including angular, parallel, and axial misalignment. Choose a jaw coupling with appropriate misalignment capabilities to avoid premature wear and failures.

- Environmental Factors: Assess the environmental conditions, such as temperature, humidity, and presence of chemicals or contaminants, as these factors can impact the coupling’s material selection and performance.

- Service Factors: Some applications may have service factors that affect the required torque capacity. Apply service factors as needed to ensure the coupling can handle the application’s demands.

- Space Constraints: Consider the available space for the coupling. Ensure that the selected jaw coupling can fit within the given space constraints.

- Compliance with Standards: If applicable, verify that the chosen jaw coupling meets industry or application-specific standards and regulations.

By taking these factors into account, engineers and designers can determine the appropriate jaw coupling size that will provide reliable and efficient power transmission in the specific application.

editor by CX 2024-01-16